Updates to Eagle Iron Works Classifying Tanks

January 14, 2025

DES MOINES, Iowa, Jan. 14, 2025 – Eagle Iron Works has recently made several updates to the valve bridge on its Water-Scalping Classifying Tanks. With these updates, there will be no changes in the function of the machine. All tanks ordered moving forward will have the new valve bridge design, however, parts and service for older models will still be available through Eagle Iron Works.

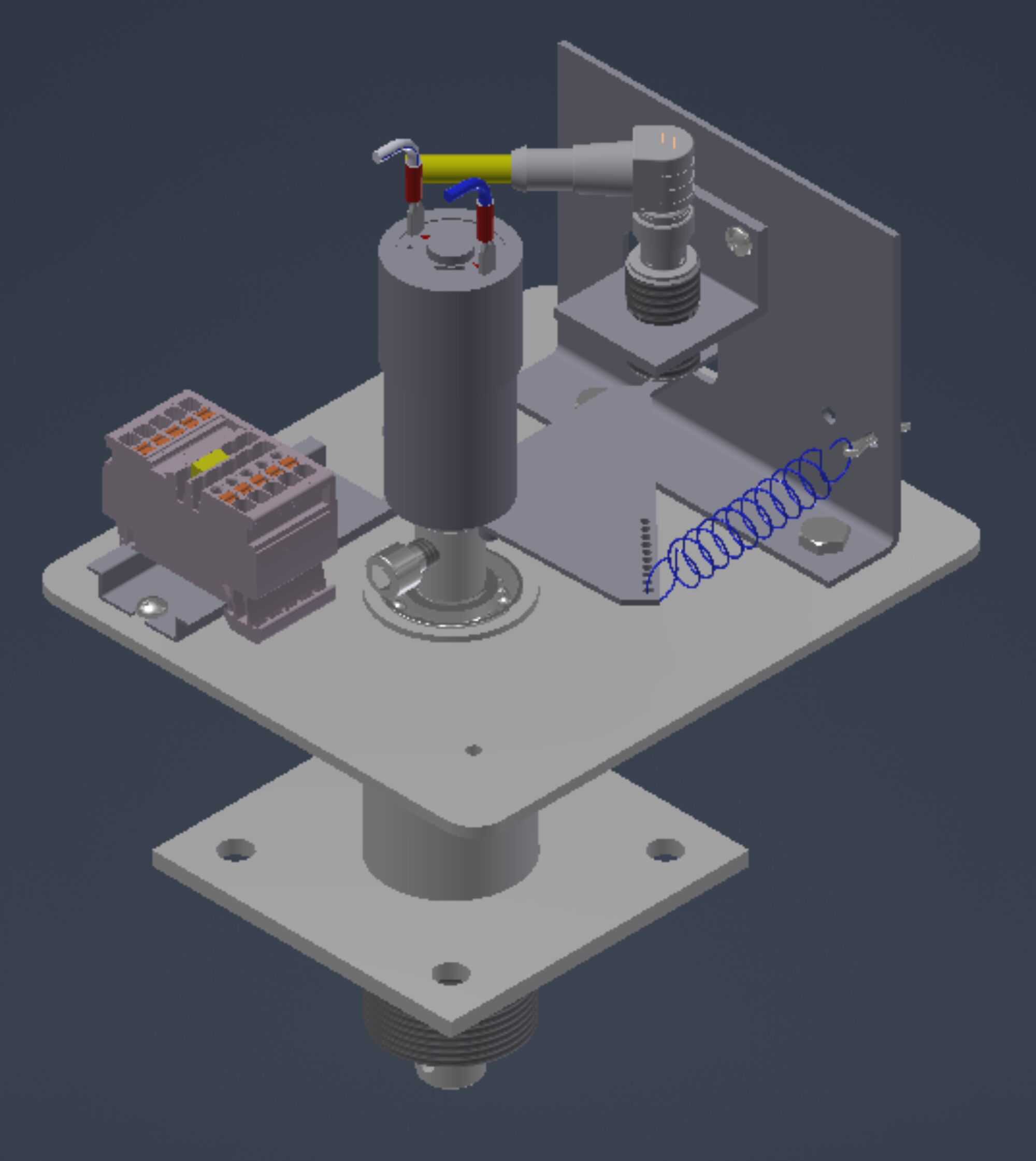

The first change to the valve bridge is that it will now be a 24VDC system instead of a 120VAC system. Switching to 24VDC is occurring more in the industry due to it being safer to work with. This change also allows for the incorporation of M12 cables for all devices inside the bridge. By using M12 cables, the ribbon cable that previously ran from a terminal block bank to each station’s junction box via enclosed wire way has been eliminated. This is very labor-intensive and can present a challenge if a wiring issue occurs on site, possibly requiring an electrician to troubleshoot. The M12 cables are very user-friendly, weather tight, and readily available if an issue arises. M12 cables are also easy to replace as they just screw into devices such as IO link blocks and bulk heads.

Next, the stall motors in the Classifying Tank Valve Bridge will now use a proximity switch instead of a mercury switch. Mercury switches are outdated and can be dangerous if broken and not disposed of properly. Mercury switch supply is also dwindling as proximity switches are becoming more common in the industry.

The next change to the design of the valve bridge is that junction boxes are being replaced with IO Link Blocks. The use of the IO Link Blocks allows for easier wiring and can also provide feedback from a station. In the previous design, if a solenoid went bad causing a valve not to cycle, the customer would not know until they viewed their product gradations. The new design allows feedback due to the IO Link Block sensing a short (failed solenoid) and will display this on the touchscreen. Each valve and stall motor assembly plugs into the IO Link Block which homeruns back to the junction box mounted to the bridge. These cables are clearly labeled under the bridge walkway to allow for maintenance without requiring drawings.

The new valve bridge design eliminates 37 pin cables. With the transition to IO Link Blocks, there is no more need for the 37 pin connectors or 37 pin cables. These pin cables are becoming less readily available with suppliers and take a lot of time to produce since each wire needs to be soldered onto each pin of the connector. There are now two cables that are thinner and more manageable that will connect the control panel with the sand tank bridge. Additionally, if a cable were to go bad or be damaged, the 37 pin connectors would take up to a week to fix. These pin cables could often cause issues if they got kinked or damaged, creating difficulty when trying to troubleshoot issues within the system. Removing the cables allows for easier troubleshooting.

Lastly, in this new design, the fused terminal blocks that were used in older systems have been removed. Instead, there are circuit breakers in place for the different stations. This eliminates the need to replace the “one and done” style fuses, and instead, the circuit breakers will be tripped and only need to be reset once the reason for the trip is resolved.

These updates to the valve bridge design are necessary for several reasons, including improved safety, ease of assembly and troubleshooting. As the original valve bridge design ages, more components are becoming obsolete and harder to source. This new design uses modern components that are more readily available and currently being manufactured, making it easier to support into the future.

Eagle Iron Works has provided aggregate processing solutions for over 150 years and looks forward to continuing to meet the evolving needs of the industry. Throughout this time, EIW has built a reputation for durability and unmatched customer service. For more information, visit www.eagleironworks.com.

###