What is the CONDOR? Here are the benefits of EIW's standard line of Screw Washers

Eagle Iron Works’ CONDOR has hatched and is ready to make your operation its new home, but what exactly will the CONDOR do for you when it gets there?

Simple — EIW’s CONDOR Coarse Material Washer will wash your crushed stone and gravel to remove deleterious material, like soluble clays and dust coatings from the crushing process. EIW’s CONDOR Fine Material Washer will wash, dewater and classify your sand or other fine material.

Like Eagle’s Classic Equipment, CONDOR Screw Washers offer a long operating life, low operating cost and a short return on your investment. They’re built using Eagle’s proven heavy-duty design and durable wear parts. They’ve got the same outboard bearings, the same shaft dimensions, the same full length curve plate, the same rising current plate, and the same adjustable weirs as Eagle's Classic Equipment. CONDOR Screw Washers are also constructed with U.S. Steel, just like Eagle’s Classic Coarse Material Washer and Fine Material Washer, and their washer tubs have the same capacities.

So What Makes the CONDOR Line Different?

The primary difference is CONDOR Screw Washers are built with Dodge Torque-Arm II reducers. These industry-recognized gear reducers allow the CONDOR screw washers a long life of continuous operation but at a more competitive price — one you’re sure to love.

Another difference is that CONDOR Screw Washers also come with the standard value line of urethane flight shoes. However, you can choose to upgrade your CONDOR’s flight shoes to the premium urethane or Eagle Armor if you wish.

With the CONDOR line of screw washers, you’ll see a quicker return on investment, yet you’ll retain the benefits you know and love about Eagle’s Classic Equipment.

Benefits of EIW’s CONDOR

- The CONDOR line of screw washers features the same physical mounting points as Eagle’s Classic products to ensure a seamless transition into your operation. If you’re looking to replace your Eagle Coarse Material Washer or Fine Material Washer, the CONDOR equivalent will have no trouble fitting in and picking right up.

- CONDOR Fine Material Washers and CONDOR Coarse Material Washers feature adjustable weirs for maximum product retention. With the CONDOR Fine Material Washers, these adjustable weirs ensure the washer tub is level even in asymmetrical conditions. Level weirs provide a low overflow velocity and allow less product to be carried away with the wastewater. The adjustable weirs also give you more control over the product size, as offsetting the weirs yields a coarser mesh material. With the CONDOR Coarse Material Washer, the adjustable end weir allows more trash to be removed from the slurry.

- CONDOR Screw Washers come with standard flight shoes and a standard-duty screw shaft; however, Eagle Armor and premium urethane wear shoes, as well as heavy-duty screw shafts, are offered as an optional upgrade.

- Each CONDOR Screw Washer comes with standard safety guarding to protect you and your personnel from the machine’s moving parts.

- Deleterious material doesn’t stand a chance with the CONDOR, which is configured for optimal particle-on-particle scrubbing and is built to withstand the same tough washing, dewatering or classification capabilities for which Eagle equipment has become well known.

- CONDOR Screw Washers are manufactured with the strong U.S. Steel, and they match the capacities of Eagle’s Classic Equipment line.

- As with all of their equipment, Eagle Iron Works offers service and support through the life of the CONDOR machines. The CONDOR comes backed with the knowledge and experience of Eagle’s application specialists and service technicians, who can help you troubleshoot, size and provide recommendations for your operation.

The CONDOR line comes in both fine material washers, with model sizes of 36”, 44”, 48”, 54” and 66”, and coarse material washers, with model sizes of 30”, 36” and 44”. Single and dual shaft models are available for each.

How the CONDOR Fine Material Washer Can Help Your Operation

The CONDOR Fine Material Washer may be one machine, but it can benefit your operation in three ways:

- Washing

- Dewatering

- Classification

Washing

The main function of the CONDOR Fine Material Washer is to wash 3/8” sand or other fine material to help you meet customer or Department of Transportation specifications. It reduces the amount of material passing the 200 mesh sieve, removes excess particles and deleterious materials, and produces a reliable and constant gradation.

The CONDOR Fine Material Washer works like this: The sand material and water enter the feedbox, where the sand settles into the pool area. The conveyor shaft continuously rotates to agitate the sand material, providing the particle-on-particle scrubbing needed to liberate deleterious materials, like coals, shales, clays and soft stones, from the sand. The unwanted material and light, fine particles are discharged along with the wastewater over the overflow weirs.

Dewatering

Dewatering occurs as the screw flights on the conveyor shaft move the heavy sand particles up the inclined washer tub, which consists of a trough with a curved plate on one side. Water is drained from the material as it is conveyed out of the pool area via the spiraled shaft and up the curve plate toward the discharge end, providing you with a drier, more saleable final product.

For maximum dewatering efficiency, ensure there is sufficient water volume in the trough opposite the curve plate. This will prevent sand from building up in this area. In addition, a drier sand product is possible by slowing down the rotational speed of the shaft, which is proportional to the volume the CONDOR will produce in tons per hour. Keep in mind, slowing down the shaft speed by 50%, will produce 50% fewer tons per hour.

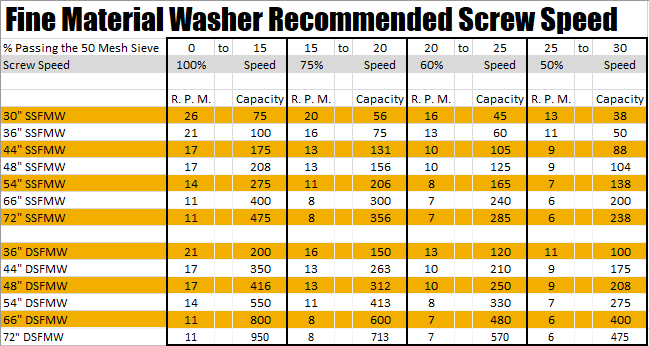

Determine the percent passing the 50 mesh sieve for the fine material product from the CONDOR Fine Material Washer using this chart.

Classification

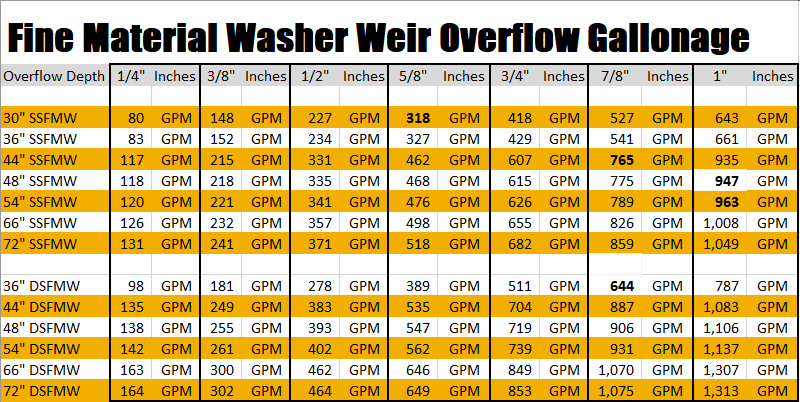

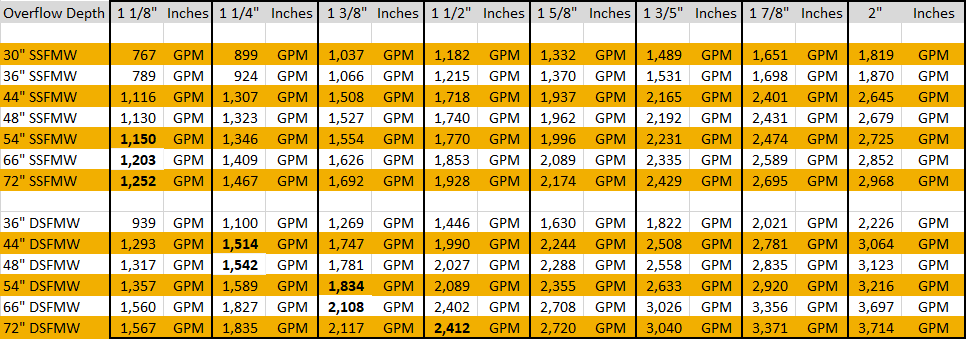

Classification is the other function of the CONDOR Fine Material Washer. Weirs should be adjusted as level as possible, ensuring even water flow for the length of the weirs. The velocity of the flow is determined by the amount of fresh water flowing to the rising current manifold. Please refer to Eagle Iron Works' gallonage chart for each specific washer size to determine the depth of water flowing over the weir, which is measured according to the desired mesh size split.

Measure the depth of the weir overflow, and consult the chart either above and below to determine the approximate hydraulic split. The numbers in bold are the recommended flow for 150 mesh split.

Note: It is important to keep the weir overflow troughs clean and free of material to make an efficient hydraulic split. The tub area should also be kept free of buildup and turbulence to prevent a loss of material overflowing with the wastewater.

How the CONDOR Coarse Material Washer Can Help Your Operation

The CONDOR Coarse Material Washer can scrub coarse aggregate 3/8” and larger, as well as remove trash material from the slurry.

Scrubbing

Crushed stone and gravel can be effectively washed with the CONDOR Coarse Material Washer. Like the Fine Material Washer, the CONDOR Coarse Material Washer employs particle-on-particle scrubbing to remove soluble clays, crusher fines and dust to provide you with a clean aggregate. The deleterious material is removed by an upward current of water and discharged with the overflowing wastewater.

Unlike the CONDOR Fine Material Washer, though, the CONDOR Coarse Material Washer uses corrugated paddles along with the wear shoes to cut through the slurry material.

Trash removal

The CONDOR Coarse Material Washer can aid in trash removal as well as provide scrubbing. When the washer tub is sloped to 18 degrees, the corrugated paddles provide a jigging action that floats sticks, roots and coal to be flushed out by the rising current along with the skimmed light-weight deleterious material.

You can customize the CONDOR Coarse Material Washer to meet the scrubbing or trash removal needs of your application by adding more paddles to the screw shaft. Adding more paddles increases the scrubbing action of the washer, resulting in a cleaner product. However, additional paddles mean less capacity, as paddles do not convey material as quickly as the heavy duty spiral segments can.

Why a CONDOR?

Designed and manufactured by a company whose reputation for building tough, long-lasting aggregate and beneficiation equipment dates back more than a century, Eagle Iron Works’ CONDOR standard line of screw washers will go to work immediately for your operation. CONDOR Screw Washers operate in the same way as Eagle Classic Screw Washers and provide the same washing, dewatering and classification functions. They can even be customized to meet the needs of your operation. It’s the few key differences, namely the Dodge reducer, that allow the CONDOR to be available at a more competitive offer.

If you are interested in a CONDOR Fine Material Washer or CONDOR Coarse Material Washer for your operation, contact Eagle Iron Works today to speak with a technical sales representative.

Don’t miss a future post about Eagle Iron Works! Subscribe to learn what Eagle equipment can do for you!