Inside a Classifying Tank: Debunking Common Myths

As with any piece of aggregate processing equipment, there can be misconceptions about how Classifying Tanks work, where they are used and what maintenance is required. Below are some common myths associated with Classifying Tanks and why these myths are simply not true.

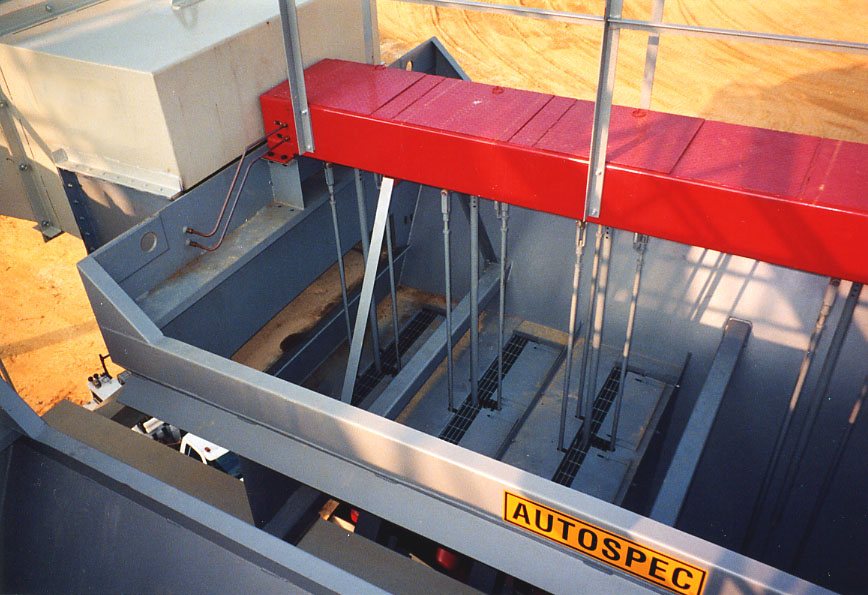

1. Myth – Classifying tanks never need to be drained or cleaned.

Classifying Tanks do need to be periodically drained and cleaned. Because you can’t see beneath the surface of the water, you can’t see if there is a buildup of material in the tank. An overly excessive amount of sand may decrease the efficiency of the equipment.

For instance, too much material buildup in the Classifying Tank can cause an issue known as rat-holing. With rat-holing, the material forms a hole above the discharge valves while the remaining material sticks to the walls surrounding the outlet.

Another instance where material buildup can affect efficiency is in the ability of the stations to discharge their contents. If material builds up in these stations, they will discharge mostly water and not material because it can’t flow through the buildup.

Draining and cleaning your Classifying Tank monthly (or more often if necessary) will help to keep your equipment running efficiently.

2. Myth - Variability in the raw feed water flow doesn’t affect gradation.

The flow needs to be consistent. If the flow of water with the sand feed varies, how the sand is classified is going to change, and it becomes difficult to make a consistent spec product.

3. Myth - Adjusting the values on the Rising Current Classifier is required.

When applications have an extreme unbalance of pit gradation or extremely difficult specifications, a standard Classifying Tanks does not provide sufficient classification to blend the desired product. The addition of a Rising Current Classifier over the first few stations on the Classifying Tank can greatly increase the efficiency of classification.

The Rising Current Classifier consists of a closed chamber with an adjustable slot extending across the top of the chamber. Water is introduced to the chamber and leaves through the slot, causing an uprising current. Any material that enters the chamber must pass downward through this rising current of water, and in doing so, the finer particles are carried further down the tank by the current and prevent fine sand from discharging with coarse sand. The Rising Current Classifier provides greater control the final product gradations by allowing only the desired sand fractions to be reblended for most construction sand specifications.

When it comes to adjusting the values on the Rising Current Classifier, generally, you can set it and forget it. However, if you notice that a sand product falls out of spec or goes out of spec, you may want to check the gradation of sand discharging from stations 1, 2 and 3 that on occasion may require the addition of water to a Classifying Tank’s Rising Current Classifier section.

It’s a rule of thumb that sand discharging from stations 1, 2 and 3 should be less than 10% passing 50 mesh. The Rising Current Classifier valve stations at 1, 2 and 3 need to be coarse to efficiently blend the intermediate and fine sands retained to make in-spec construction products.

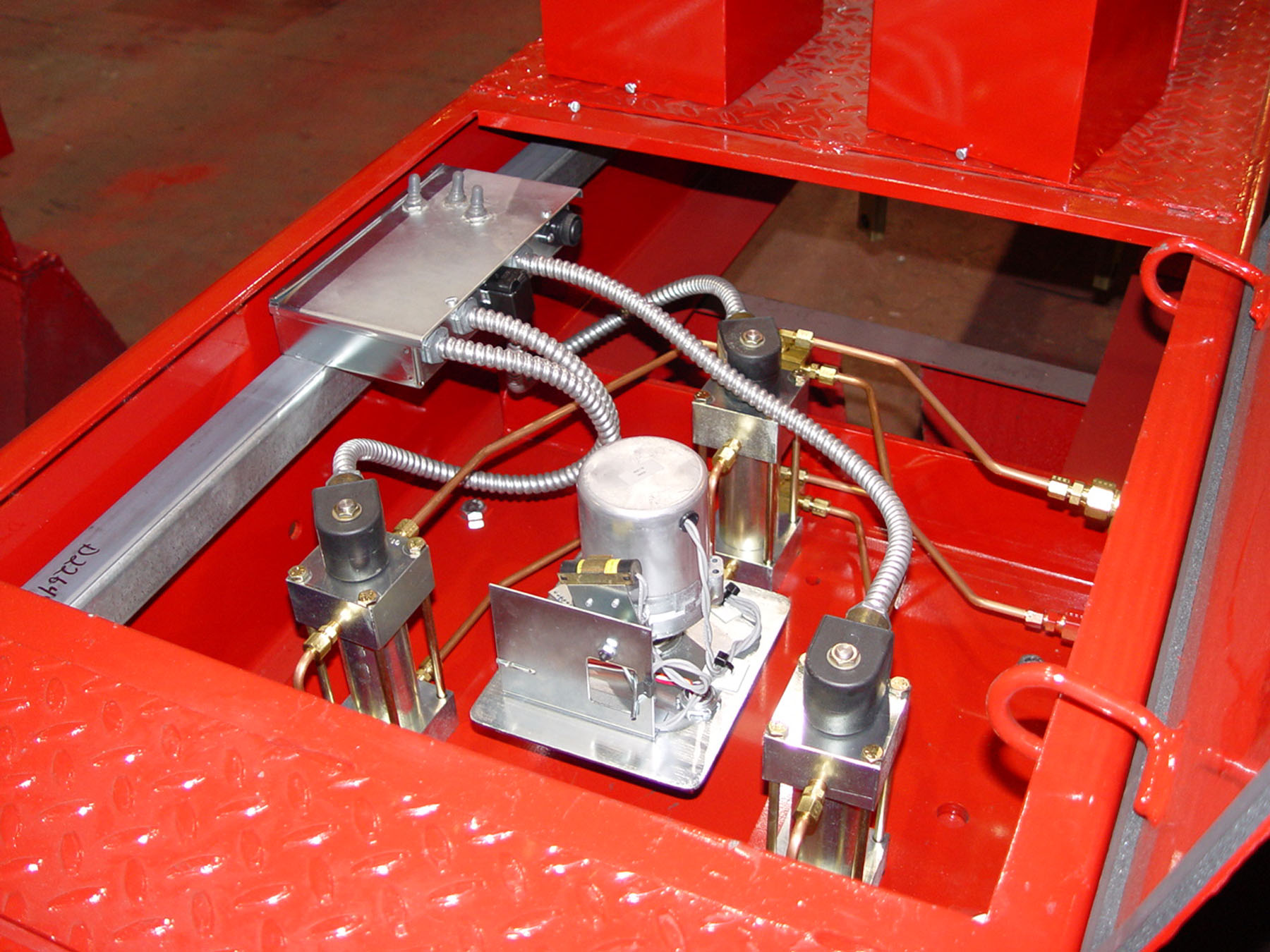

4. Myth - The oil in the hydraulic reservoir never needs to be changed.

To keep your Classifying Tank operating at peak efficiency, you need to change the oil in the hydraulic reservoir in accordance with the operator’s manual. Failure to change the oil can lead to serious problems down the road, which can result in costly repairs or unexpected downtime.

Your operator’s manual will tell you how much of what kind of oil to add and when.

5. Myth - Typical buildup of material in the first three stations surrounding the hydraulic cylinder in the valve bridge or control enclosure doesn’t affect the efficiency of the machine.

It is good practice to avoid buildup near the hydraulic cylinders and motors to prevent premature failure of these components. Wet material around these electrical lines and motors can also be and operating hazard.

6. Myth - Adding a gallon of oil daily to keep the system operating is just a minor leak.

If you have to add a gallon of oil to your Classifying Tank, you most likely have a leak that needs to be addressed. If there’s a leak in the system, find it and fix it for continuous smooth operation.

7. Myth - Classifying tanks are proper for any sand classification requirement.

Classifying Tanks are commonly used to produce specification construction grade sands such as concrete, asphalt and mason sand. Some Classifying Tanks have also been used to produce sands for golf courses in accordance with the United States Golf Association's specifications.

While Classifying Tanks are great for meeting construction aggregate specifications, removing surplus water ahead of a Fine Material Washer and diverting excess sizes from deposits with bellies of certain mesh sizes, they are not suitable for producing the sharp cuts required in frac sand products.